Demister Pads/Coalescer/Mesh Pad are permeable covers of wire or plastic sewed work, planned and developed for proficient and efficient expulsion of entrained fluid beads from vapour streams. The cushions can be manufactured in an ideal size and shape. Typically, demister cushion is introduced, so that vapour stream is upward. Whenever vapour and entrained fluid beads go through a demister cushion, the vapour passes effectively yet fluid drops, because of their more noteworthy inactivity, can’t make the essential sharp transforms and are tossed into contact with the wire surfaces and quickly held there.

As more beads enter the cushion and gather on the wires, they develop in size, run down the cable to the base surface of the work separator and tumble from the unit. Overhead vapour is presently free of entrained fluid.

Demister cushion/Coalescer/Mesh Pad counteract the loss of essential item and delivers brilliant condensate appropriate for utilizing a kettle’s feed water. The applications are in the processing plant vacuum towers, evaporators, treatment facility lube towers, steam drums, safeguards, scrubbers, separator vessel and thump out drums.

The appropriate speed relies upon fluid thickness, surface pressure, bead size and amount of entrainment. The weight drop is insignificant, and the productivity is high relying upon vapour and fluid stacking.

The Demisting Process :

The working standard behind the fog eliminator is straightforward. As the wet vapour stream ascends through layers of contracting surfaces inside the weaved and creased wire network, entrained as they persistently sway each surface. The gas inside the vapour stream keeps on ascending as the heavier fluids isolated, connect and coalesce into beads inside a work. As the beads develop, so does their weight until they tumble to the base of the vessel because of gravity. Fluid aggregations would then be able to be depleted out of the base as the gas is directed through the highest point of the Vessel.

Our Applications

Assimilation segments

Refining sections

Steam Boilers

Gas and Air scrubbers

Oil Mist Separation

Profluent gas treatment in Sulphuric Acid Factories.

Vacuum Towers and Drying Towers

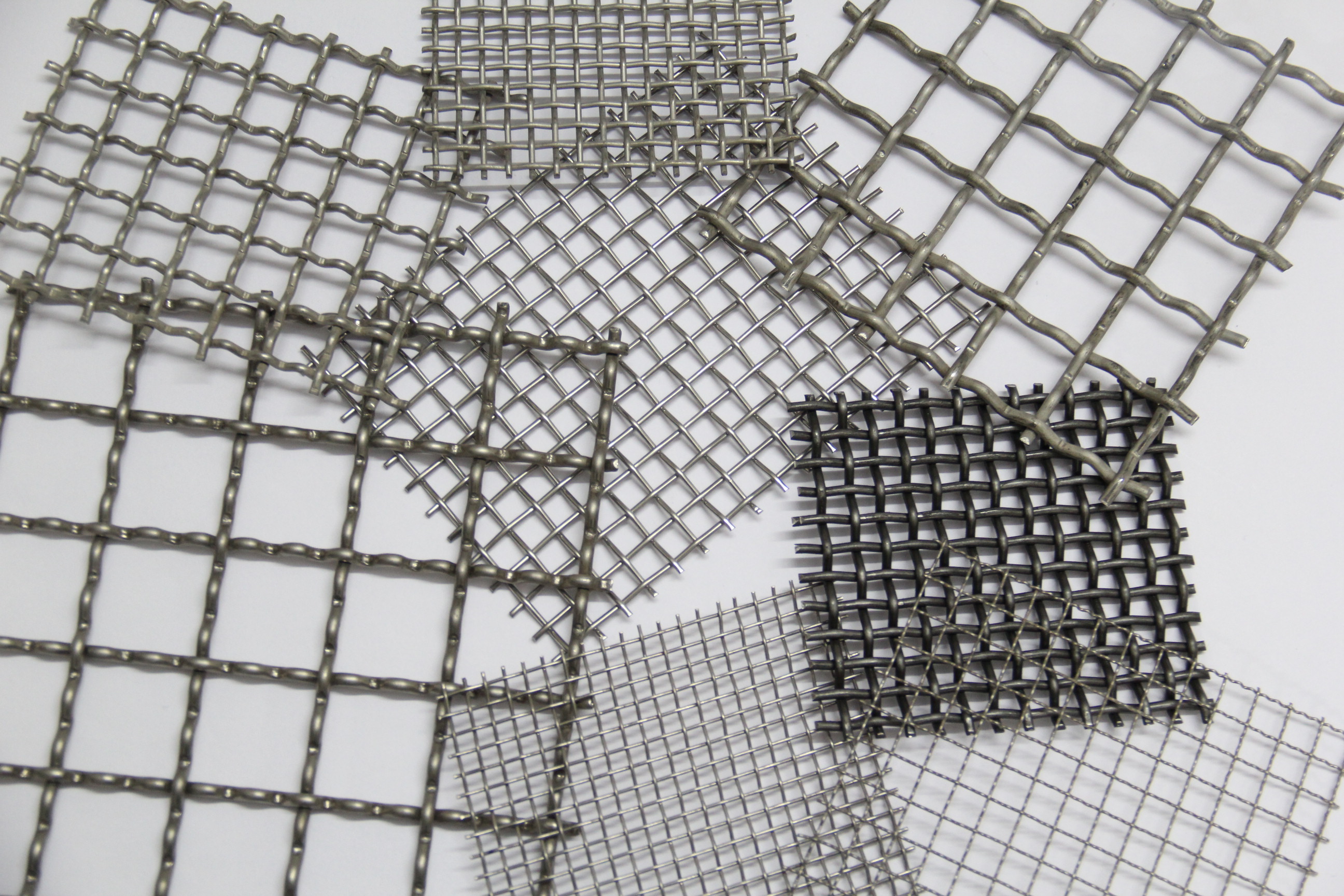

Materials of Construction:

Stainless Steel

Polypropylene

Nickel

Monel

PVDF

PTFE

Aroused steel

Glass fibre